Health, Safety Engineering & Management System

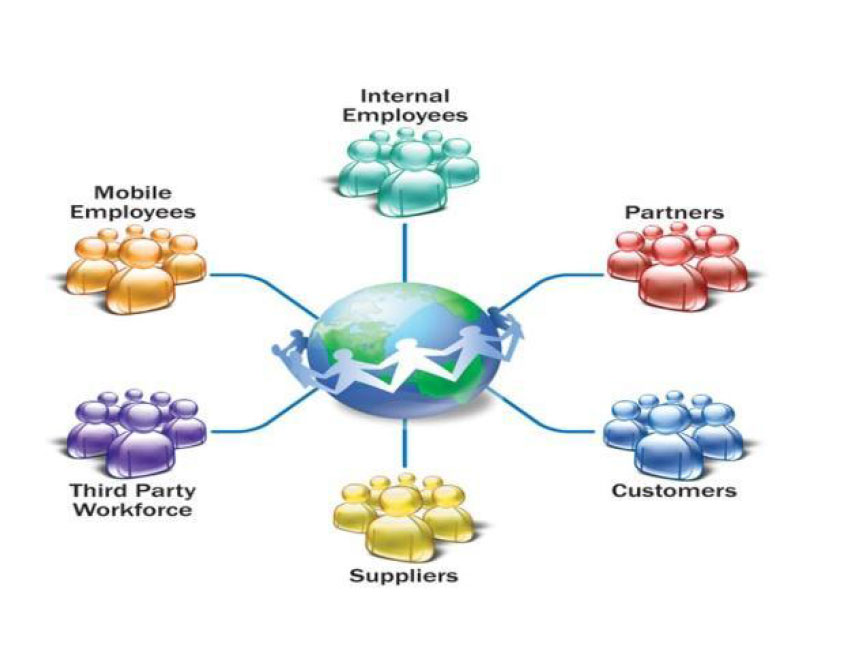

It is the policy of Alexandria Integrated Systems and Consultations (AISC GROUP) that all persons are entitled to a healthy, safe, and secure environment. To that end, the health and safety of all our employees and clients shall be a constant determining factor in our project planning stages, and in our everyday work. AISC GROUP believes that safety is not only a key part of every job, at every level of the organization, but that culture and environment can be created in which safety hazards or incidents can truly be prevented.

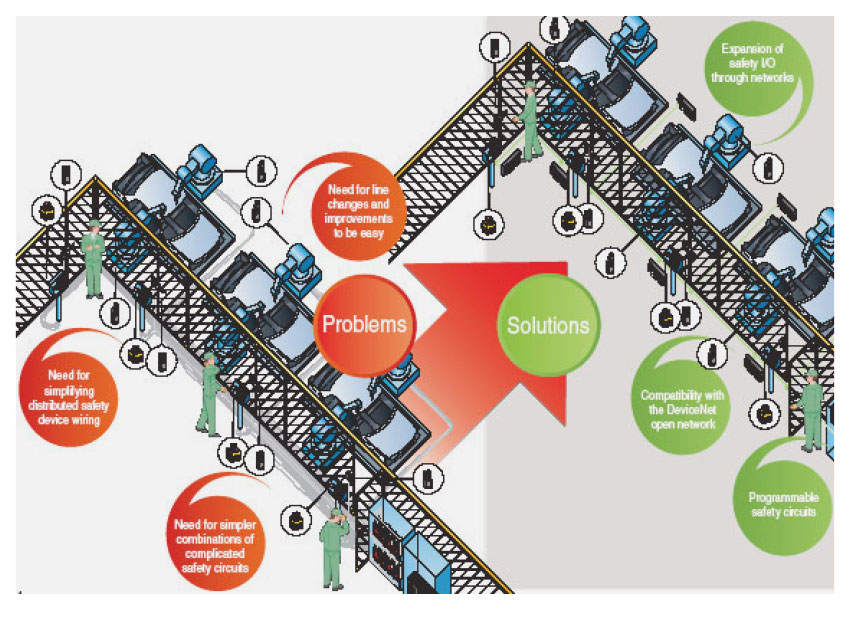

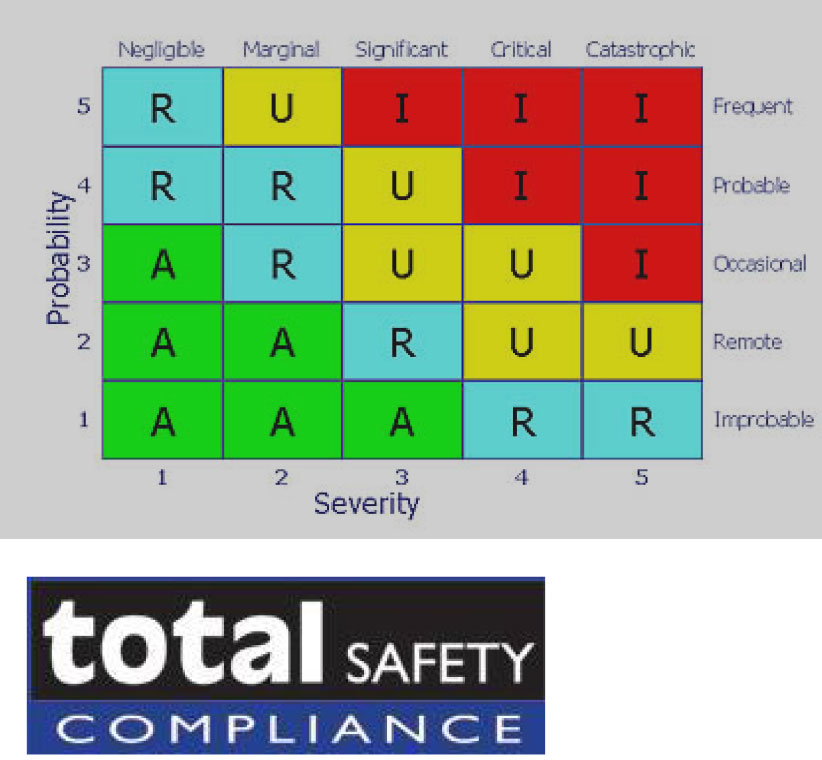

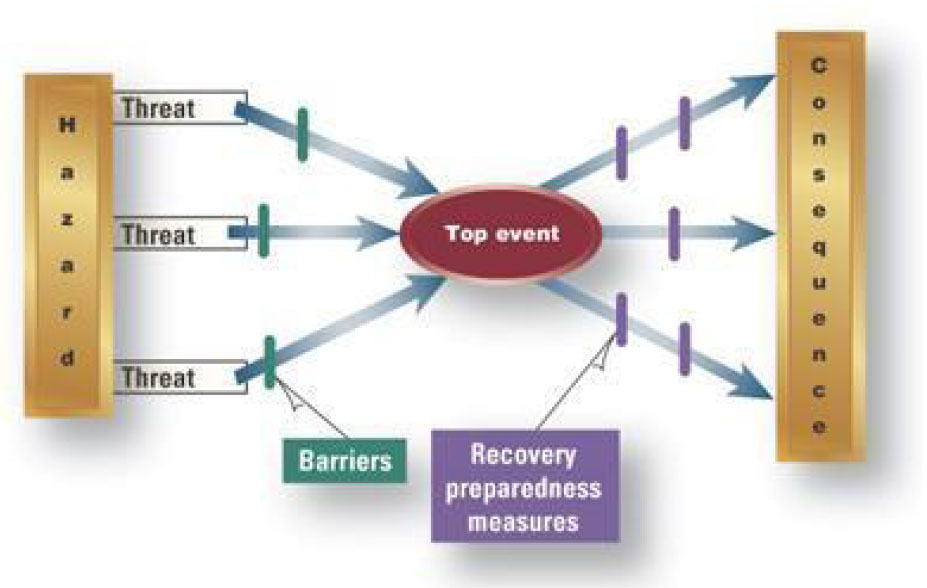

The desire of most companies in all business is to create an environment and culture where safety and environmental hazards are eliminated – however, the road to this objective has not been an easy or obvious one – there are still environmental events, injuries, and deaths that occur on a day to day basis. AISC GROUP believes that while safety moments, safety statistics, hazard assessments, etc. are important tools in combating unsafe acts, the true path to a “culture of safety” is through the actions and visibility of leadership in relation to HSE issues and visibility to events when they do unfortunately happen. In this manner, HSE becomes a continuous life learning process for those involved.

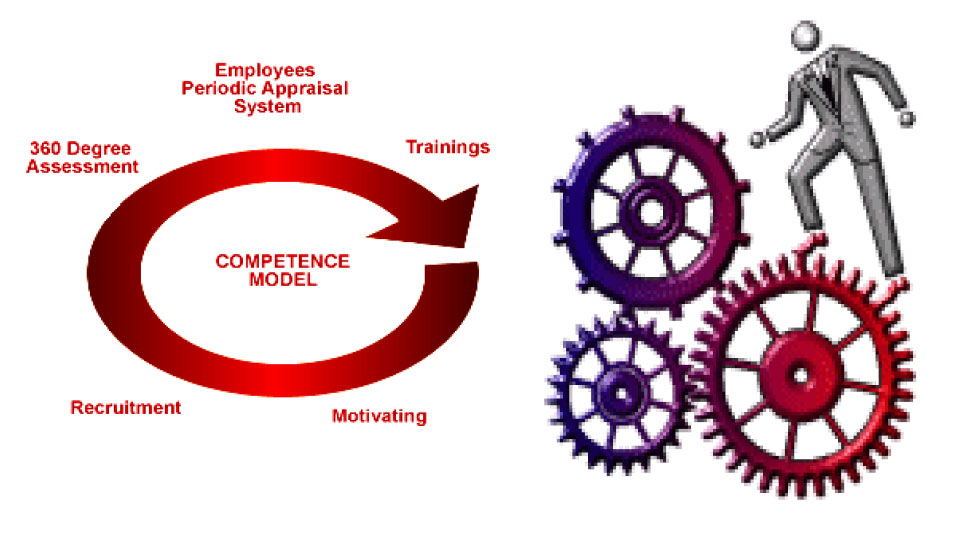

Based on this practical and simple philosophy AISC GROUP leadership is responsible to develop the proper attitude and standard job planning performance that will enable our organization to meet our safety expectations and objectives and those of our clients. The commitment to the program by all levels of leadership is firm, unwavering, and transmitted to all levels of our organization in every aspect of our work. Our employees, in turn, are aware of our leaderships’ commitment to the prevention of harm and are prepared to implement that standard of commitment, which enables us to be a leader in our industry. This policy illustrates the recognition and acceptance by our leadership of the fact that safety and production are inseparable; therefore, planning for accident prevention and zero harm shall be incorporated into all phases of our work.

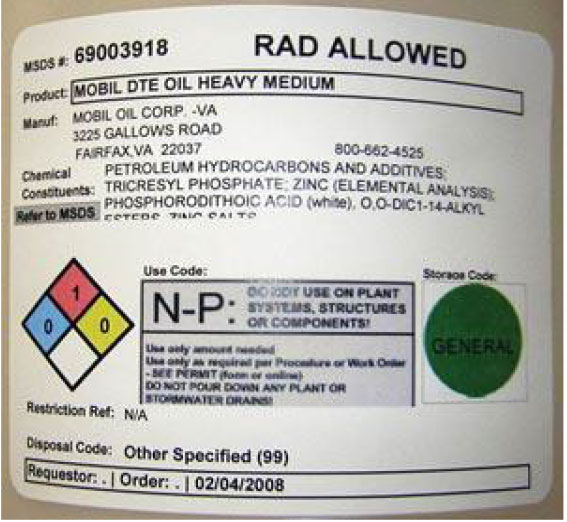

Our approach is based on a unique blend of creative engineering, scientific and management skills, proven methodologies, up-to-date analytical tools and data, and a practical outlook. Our collective expertise and experience mean we provide solutions for our clients, not more problems. As a result, we have a reputation for successfully delivering and providing value for money.

AISC GROUP provides practical guidance to assist you in finding the right health, safety, and environmental consultancy solutions for your organization. We will ensure that the solution is acceptable to you and reflects the requirements of current health, safety, and environmental legislation. The following is just a small example of the types of services we can provide to you as a leading health and safety, environmental management consultant team.

We can perform the full and complete services as your safety director or perform monthly scheduled site audits or training classes. No matter what size the company, AISC GROUPis cost-effective. We focus on providing comprehensive services to companies with one project or companies with multiple job sites. We are ready to handle any situation and each consultant is committed to maintaining the best performance for each client. Each consultant is readily accessible by his cell phone or through AISC GROUP’s main office. No matter what safety needs, we are your best choice.