Environmental Systems Engineering and Management

Environmental engineering has become an increasingly important discipline due to the complexity and multi-disciplinary nature of the environmental issues dealing with human health and ecosystem protection. To find cost-effective engineering solutions to these complex issues, it is important to acquire broad-based education and professional training in interdisciplinary fields of physical, chemical, and biological principles, resource management, and mitigation measures besides in-depth knowledge in environmental engineering. This course-based program will cover a wide range of related topics, such as environmental law and management; human health and ecological risk assessment; remediation technology; treatment processes of drinking water and wastewater; contaminant transport and environmental modeling; environmental sampling; and pollution-control engineering. To apply the concepts learned in the classroom and laboratory environments, students will work in teams on an engineering project for two terms. In order to acquire broad-based knowledge in the field, students will be encouraged to take courses from other disciplines in the university.

The program can be completed on a full- or part-time basis. The duration of the full-time program is normally 1 to 2 years.

Course Requirements

The total credit required to complete this course-based program is 30 credit hours. It will take from the following three groups.

- Environmental Engineering Project (six credit hours)

- Environmental Engineering Project A (zero credit hours)

- Environmental Engineering Project B (six credit hours)

Five core courses (three credit hours each)

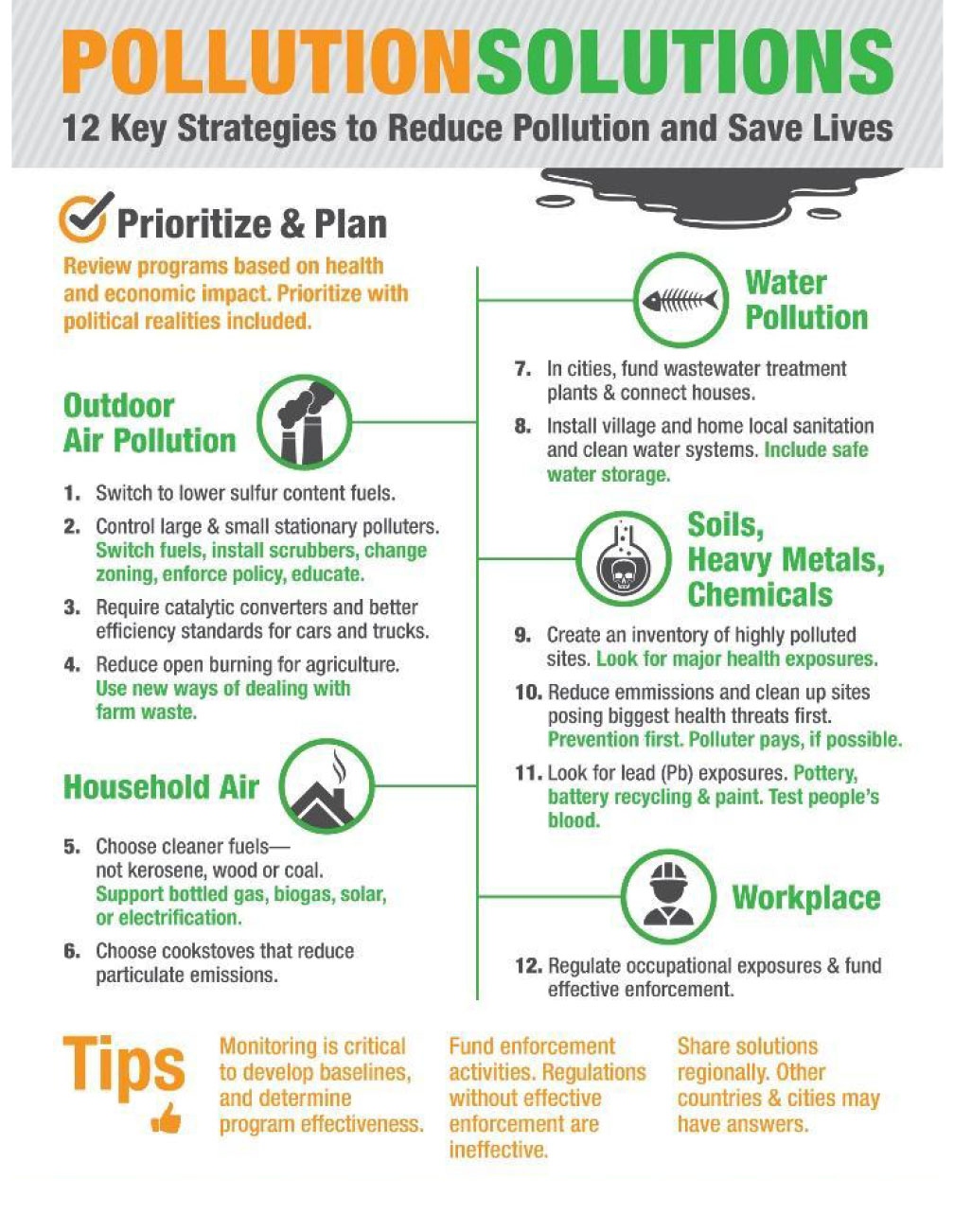

- Environmental pollution and mitigation

- Environmental risk assessment

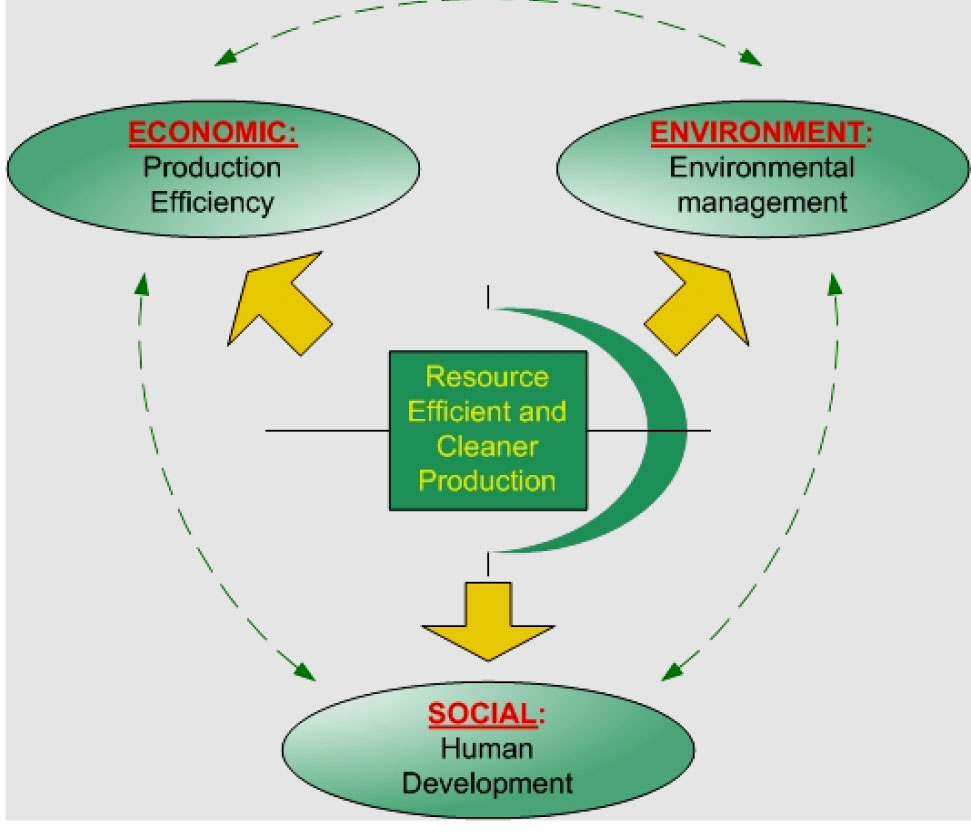

- Environmental management system

- Environmental systems engineering

- Environmental laboratory

Three elective courses from the following list (three credit hours each)

- Environmental sampling and pollutant analysis

- Water and wastewater treatment

- Soil remediation engineering

- Environmental statistics

- Air pollution

- Environmental impacts of offshore oil and gas operations

- Environmental policy and regulations

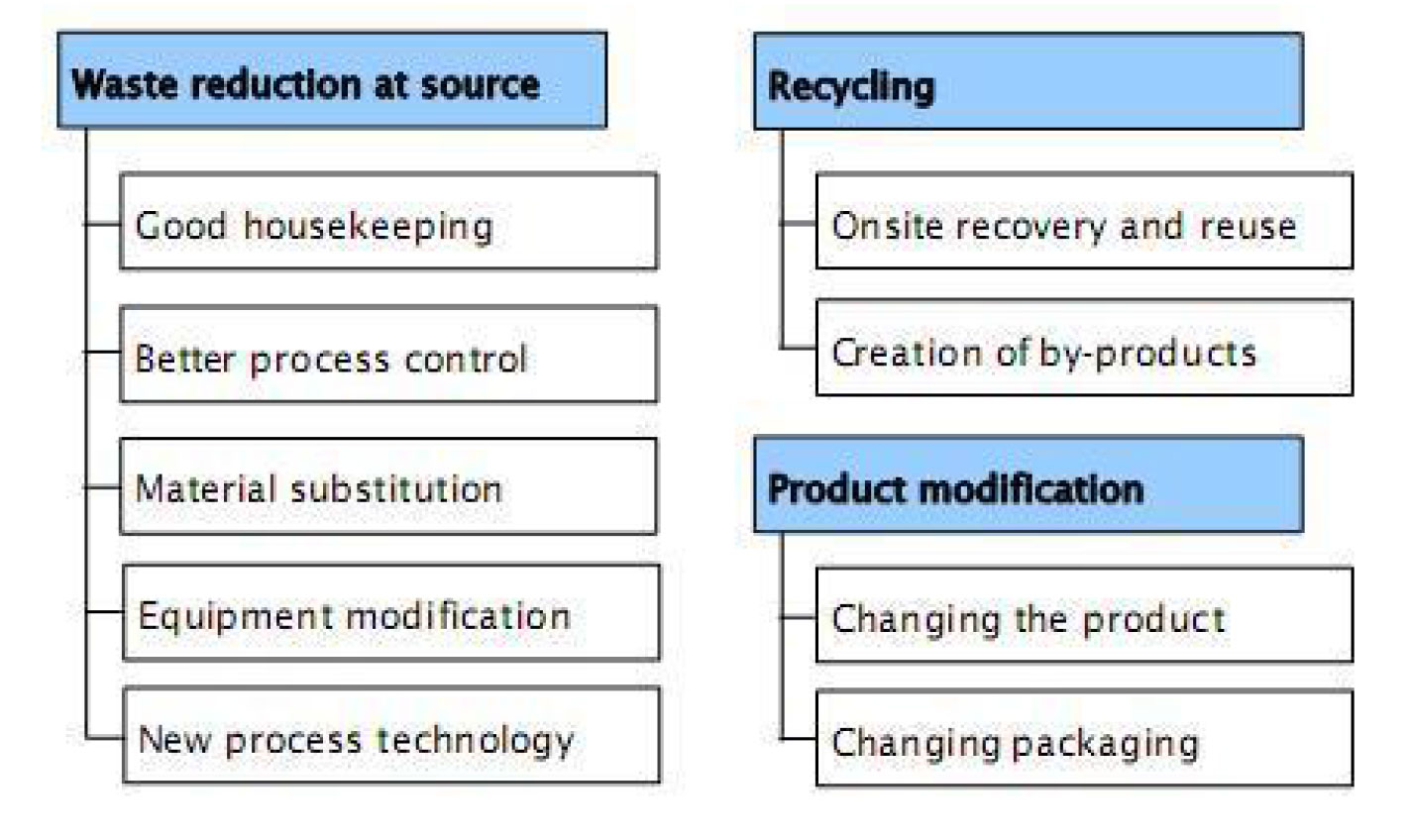

- Pollution prevention

- Special studies topics

- Earth and ocean sciences

- Environmental chemistry & toxicology

- Applied ecology

- Conservation of natural resources