HACCP ISO 22000:2018

Food safety management systems

ISO 22000 is a generic food safety management standard; it can be used by any organization directly or indirectly involved in the food chain. It doesn’t matter how complex the organization is or what size it is, ISO 22000 can help ensure the safety of its food products.

The ISO 22000 international standard specifies the requirements for a food safety management system that involves the following elements:

- Interactive communication

- System management

- Prerequisite programs

- HACCP principles

ISO 22000 integrates the principles of the Hazard Analysis and Critical Control Point (HACCP) system and application steps developed by the Codex Alimentarius Commission. By means of auditable requirements, it combines the HACCP plan with prerequisite programs. Hazard analysis is the key to an effective food safety management system, since conducting a hazard analysis assists in organizing the knowledge required to establish an effective combination of control measures. ISO 22000 requires that all hazards that may be reasonably expected to occur in the food chain, including hazards that may be associated with the type of process and facilities used, are identified and assessed. Thus, it provides the means to determine and document why certain identified hazards need to be controlled by a particular organization and why others need not.

HACCP ISO 22000:2018 Benefits

- More efficient and dynamic food safety hazard control

- Systematic management of prerequisite programs

- The valid basis for making decisions

- Increased due diligence

- Control focused on what is necessary

- Saves resources by reducing overlapping system audits

- Organizes and targets communication among partners

- Resource optimization

- Improves documentation

- Better planning, less post-process verification

How can AISC-GROUP help?

Our Team offers a variety of Consulting Services and Solutions.

- Provides a well-planned and stage-by-stage audit program.

- A sound, coherent and non-disruptive assessment. Used by organizations across the food chain to help deliver food that’s safe to eat to consumers, ISO 22000:2018 is an excellent framework to help implement a food safety management system (FSMS).

How food is grown, transported, manufactured, and even consumed has changed significantly since the original standard was published over a decade ago. The new standard considers these changes and aims to help organizations reduce food safety hazards.

Steps Of Certification

Conduct a Hazard Analysis. There are 11 Stages to this

- Define Terms of Reference

- Select the HACCP team

- Describe the product

- Identify intended use

- Construct a flow diagram

- On-site verification of flow diagram

- List all hazards and control measures

- Determine the Critical Control Points (CCPs) using a decision tree. These are the points where hazards must be eliminated or minimized.

- Establish Critical Limits which must be met to ensure the CCP is under control.

- Establish a system for monitoring the control at CCPs.

- Establishing the corrective actions to be taken when monitoring indicates that a particular CCP is not under control6. Establish procedures for verification to confirm that the HACCP system is working correctly.

Key changes in ISO 22000:2018

These are some of the key changes to consider:

1) Changes due to the adoption of HLS

ISO 22000:2018 is based on Annex SL – the ISO high-level structure (HLS) that brings a common framework to all management systems. This helps to keep consistency, align different management system standards, offer matching sub-clauses against the top-level structure and apply common language across all standards. With the new standard in place, organizations will find it easier to incorporate their food safety management system into core business processes and get more involvement from senior management.

2) An integrated approach

- Business Context and interested parties: Chapter 4.1, external and internal issues, introduces new clauses for systematic determination and monitoring of the business context, and Chapter 4.2, needs and expectations of interested parties, introduces demands to identify and understand factors that can (potentially) affect the ability of Management System to reach the intended results.

- Strengthened emphasis on leadership and management commitment: Chapter 5.1 now includes new demands to actively engage and take accountability for the effectiveness of the management system.

- Risk management: – Chapter 6.1 now requires companies to determine, consider and, where necessary, act to address any risks that may impact (either positively or negatively) the ability of the management system to deliver its intended results.

- Strengthened focus on objectives as drivers for improvements: these changes can be found in Chapter 6.2, and performance evaluation chapter 9.1.

- Extended requirements related to communications: Chapter 7.4 is now more prescriptive in respect to the “mechanics” of communication, including determination of what, when and how to communicate.

- Less strict requirements for a food safety manual: – the change is introduced in chapter 7.5. It is still required to have documented information. Documented information shall be controlled to ensure it is adequately protected (ref. 7.5.3). The explicit requirement to have a documented procedure has been removed.

3) Other changes that are specific to ISO 22000 and food safety management

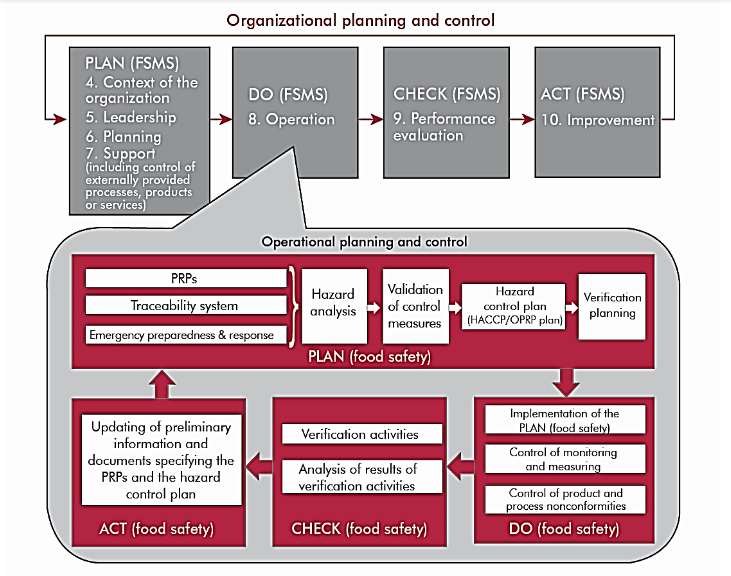

- The PDCA cycle: the standard clarifies the Plan-Do-Check-Act cycle, by having two separate cycles in the standard working together: one covering the management system and the other, covering the principles of HACCP.

- The scope now specifically includes animal food: food for animals not producing food for human consumption. Feed is intended to be fed to food-producing animals.

- Some important changes in the definitions: ‘Harm’ is replaced by ‘adverse health effect’ to ensure consistency with the definition of the food safety hazard. The use of ‘assurance’ highlights the relationship between the consumer and the food product, based on the assurance of food safety.

- Communicating the food safety policy – Chapter 5.2.2: Explicitly requires the management to facilitate understanding of the food safety policies by employees.

- Food Safety Management System Objectives: Establishing objectives for the food safety management system is further specified in Chapter 6.2.1 and includes items such as e.g. ‘consistent with customer requirements, ‘monitored’ and ‘verified’.

- Control of externally provided processes, products, or services – Chapter 7.1.6: This clause introduces the need to control the suppliers of products, processes, and services (including outsourced processes) and to ensure adequate communication of relevant requirements, to meet the food safety management system requirements.

In addition, there are several key changes in the ISO 22000:2018 compared to ISO 22000:2005 related to the HACCP systematics.

- A stronger emphasis on the responsibility of leadership

- Applies a risk-based approach to the development of the FSMS

- Clarification of key concepts including:

- The Plan-Do-Check-Act cycle, by having two separate cycles in the standard working together with one covering the management system and the other covering the principles of HACCP

- The differentiation of key terms including critical control points (CCPs), operational prerequisite programs (ORPs), and prerequisite programs (PRPs)

Improved compatibility with other ISO management system standards through the realignment of the content of the standard to the high-level structure

Leadership and empowerment

There is a much greater focus on top management to demonstrate leadership and commitment with respect to the FSMS and food safety policy. Additionally, top

management needs to make sure that all responsibilities have been assigned, communicated, and understood across your organization. The top management has a responsibility to ensure that the importance of effective food safety is communicated and understood by all parties and ensure that the FSMS achieves its intended outcomes.

Process and risk-based thinking

In addition to making ISO 22000 and the resulting FSMS easier to integrate with other ISO management systems, the new version of the standard also introduces the Plan-Do-Check-Act (PDCA) cycle and risk-based thinking. By combining PDCA and risk-based thinking to manage business risk with HACCP to identify, prevent and control food safety hazards, ISO 22000 helps organizations to reduce exposure to risk and improve safety.

This combines both organizational and operational risk management into one management system. Organizationally, this approach provides the opportunity to consider all the different things that might impact your company, both good and bad. This allows you to prioritize the objectives of your FSMS so that it is implemented in a way that can accommodate the effects of these risks.

On the operational side, risk-based thinking and implementation are based on the principles of HACCP that are often associated with food safety management. How they interrelate can be seen in the diagram below.

The potential benefits of combining risk-based thinking, PDCA, and the process approach include:

- Focusing your FSMS and activities on higher-risk processes

- Understanding how processes within your organization are interdependent

- More effective use of resources

- Improved agility in meeting the requirements of new customers and/or meet new requirements established by existing customers

An important new clause

Clause 4: Context of the organization

The intent of this clause is to provide a high-level, strategic understanding of the important issues that can affect, either positively or negatively, the way your organization manages food safety. It gives your organization the opportunity to identify and understand factors and parties that affect the intended outcome(s) of the FSMS. It also addresses the concept of preventive action.

Your organization will need to determine external and internal issues that are relevant to its purpose: what are the relevant internal and external issues that

could have an impact or effect on the FSMS in achieving its intended outcome(s) ?

The term ‘issue’ covers not only problems but also important topics for the FSMS to address, such as compliance obligations that the organization might set

for the FSMS. Importantly, those issues should include not only conditions that the organization affects but also those that it is affected by. Some further general guidance on ‘issues’ is given in Clause 5.3 of ISO 31000:2009.

Secondly, you will also need to identify the ‘interested parties’ relevant to your FSMS. These groups could include customers, consumers, suppliers, and even

non-government organizations. Determining their relevant needs and expectations is now part of establishing the context for your FSMS. Each organization will have its own unique set of ‘interested parties’ and these may change over time.

Once the context has been established, the scope of the FSMS has to be determined in relation to various additional factors.

Finally, the last requirement of Clause 4 is to establish, implement, maintain and continually improve the FSMS.

This requires the adoption of a process approach and although each organization will be different, documented information such as process diagrams or written procedures can be used to support this.